-

Home

-

Assemblies

- Assemblies Magnet

- pot magnet

- Rubber Coated Magnet

- Channel Manget

- Magnetic Door Catch

- Cow magnet

- Magnetic wheel

- Magnetic Coupling

- Laminated Magnets

- Linear Motor

-

Magnets

- Pickup Magnet

- AlNiCo Pickup Magnet

- Ferrite Pickup Magnet

- NdFeB Pickup Magnet

- NdFeB Magnet

- Disc Magnet

- Block Magnet

- Cylinder Magnet

- Ring Magnet

- Arc Magnet

- Irregular Magnet

- Micro Magnet

-

Product Video

-

Paid Service

-

Contact us

- About us

- Contact us

-

Home

-

Assemblies

- Assemblies Magnet

- pot magnet

- Rubber Coated Magnet

- Channel Manget

- Magnetic Door Catch

- Cow magnet

- Magnetic wheel

- Magnetic Coupling

- Laminated Magnets

- Linear Motor

-

Magnets

- Pickup Magnet

- AlNiCo Pickup Magnet

- Ferrite Pickup Magnet

- NdFeB Pickup Magnet

- NdFeB Magnet

- Disc Magnet

- Block Magnet

- Cylinder Magnet

- Ring Magnet

- Arc Magnet

- Irregular Magnet

- Micro Magnet

-

Product Video

-

Paid Service

-

Contact us

- About us

- Contact us

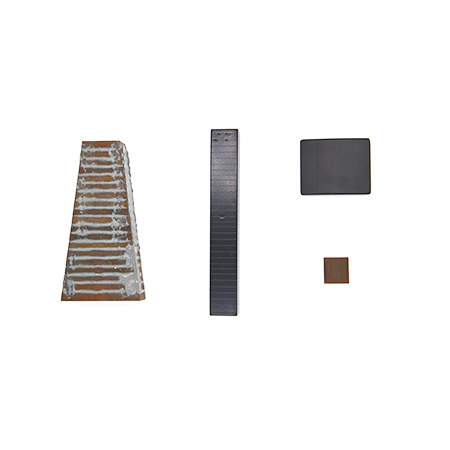

01 Laminated Magnets Basic Information

02 What is Laminated magnets?

Laminated magnet is also named Stack magnets, Segment magnets. Laminated magnet is to cut the whole magnet into many small magnets, and then use specific glue to bond together. These small magnets are insulated from each other. When the permanent magnet motor is running, the motor will generate harmonic and the magnet will generate skin effect, these all will bring a lot of eddy current loss. And then, the temperature of permanent magnet rises, which results in irreversible demagnetization and affects the safety and stability of motor operation. So the design of laminated magnet can just cut down this risk. It can reduce eddy current Loss in high efficiency motors. High efficiency demands the best materials, and the laminated rare earth magnets are proven to reduce eddy current losses in high efficiency motors. Fewer eddy current losses means lower heat and greater efficiency.

03 Purpose

① To reduce magnetic eddy current loss

② Remaining the same magnetic properties with the whole magnet or even superior.

04 Technical requirement

① The thinnest available insulating layers within 0.04mm.

② The max layers are 40.

③ The whole geometric tolerance is within 0.05mm.

④ These small magnets are insulated from each other.

⑤ Magnet layers from 0.5 mm and up to custom shapes and sizes in neodymium magnets.

⑥ The adhesive strength of the glue can reach more than 50 MPa.

05 Application scope

Now aerospace, automotive, motorsport, and industrial markets are turning to laminated rare earth magnets, and are working to balance the tradeoff between power and heat.

High quality provider